Mit-Ivy endistri metal avanse Acrylic Latex Fermeture Jadendanfan ak ekselan pouvwa penetrasyon

Aplikasyon

Li te gen adezyon ekselan nan substrats asye ak menm jan dlo ki baze sou primè, ak ekselan pwopriyete fizik ak mekanik apre vag penti a sèch.

5. Fim nan penti gen prezèvasyon limyè ekselan ak prezèvasyon koulè apre siye.

Rekòmande aplikasyon Li apwopriye pou pwoteksyon drenaj nan kamyon, pati machin, limyè ekipman endistriyèl, elatriye kote gwo pwoteksyon yo mande yo.

Done teknik Koulè asòti

Sifas sèk (50% miscibilite) 15 ℃ C <1h ; 25'C <0.5h

Solid sèk (50% imidite) 15'C <48h; 25 ° C <24h

Anvayisman "kg.cm" 50

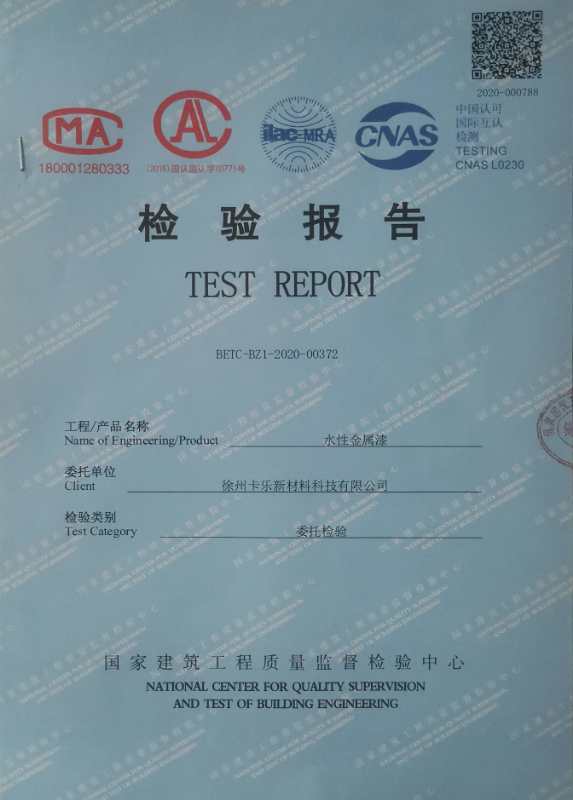

Dlo (50 ± 5μm) 72h fim penti pa anpoul, pa ede tonbe, pa rouye.

Dite 0.3 (doub pandil) mekanik pwopriyete tès fim epesè (23 ± 3jμm)

Adhesion (Hegelian) Nivo 1

Sifas tretman Sifas la nan materyèl la kouvwi yo ta dwe gratis nan imidite, lwil oliv, asid kabòn ak sann.

Detay rapid

Steel ak po oksid: eksplozif piki oswa metòd eksplozif sab tankou pwosesis nan nivo Sa2.5, kote eksplozif sab pa ka fè yo ta dwe mekanikman poli oswa

Chimik trete yo retire tout k ap flote zepòl kase.

Steel san po oksid: sandblasted (shotblasted) Sa2.5 oswa lè-aktive, elektrik zouti fanm k'ap pile St3.

Soudi, flanm dife-koupe oswa koreksyon fedatifis nan zòn vout boule: fanm k'ap pile nan nivo St3.

Sèvi ak materyèl ak fim penti fin vye granmoun: retire patikil ki lach fin vye granmoun penti ak rouye, ak sab nan St3 ak lè oswa zouti elektrik sable.

Pake penti tipik ka itilize ak H902 dlo ki baze sou Jadendanfan, oswa itilize pou kont li kòm yon kouch jeneral dekoratif, oswa itilize ak lòt kalite pwodwi Jadendanfan (bezwen matche pou verifikasyon).

Construction data Table dry (50% temperature) 15'C<th;25℃C<05h Actual dry (50% humidity) 15℃C<24h;25℃<12h Density about 1.1-1.20g/cm' Theoretical coating rate 0.15-0.2kg/m' (dry film 40-50) μm)

It is recommended to apply 2 coatings, which can be applied in the way of warm touching temperature to ensure that the dry film is 40-50μm.

To be sanded and finished with sandpaper.

Construction method Air or robot spraying is possible. Mix the paint before use, adjust the viscosity according to the construction method.

Add 5-15% of water. Add water and stir evenly, then leave the surface to work without bubbles.

Construction environment 1. The brain playground should have good ventilation and dust removal facilities to ensure the quality of construction.

2. The construction should be carried out under the condition that the mixing degree is above 5℃C and the relative humidity of the environment should be <70%.

3. The substrate temperature shall be not less than 5' and shall be more than 3'C above the air dew point temperature.

washout

| Vehicle Type | 100% Acrylic Latex | |

| COMPOSITION (nominal) | Pigment : Lightfast Non-Lead Pigments & Mineral Extenders.

Blinder : Acrylic Emulsion. Solvent : Water. |

|

| Volume Solids | 31.8% | |

| Coverage per Gallon at Recommended Film Thickness | 400 –450 Sq. Ft. (37-42 m2) | |

| Recommended Film Thickness

(Depending on surface texture and porosity. Be sure to estimate the right amount of paint for the job. This will ensure color uniformity and minimize the disposal of excess paint) |

Dry 1.2 mils

Wet 3.8 mils |

|

| Dry Time @ 77° F (25° C) @ 50% RH

(High humidity and cool temperatures will result in longer dry, recoat and service times.) |

To Touch 1 Hour

To Recoat 2 to 4 Hours |

|

| Dries By | Evaporation, Coalescence | |

| Viscosity | 99 ± 2 KU | |

| Gloss / Sheen | Flat (5-10 @ 85°) |

| Shipping time by Sea (Just for reference) | ||||||||

|

North America |

11~30 days | North Africa | 20~40 days | Europe | 22~45 days | South-east Asia | 7~10 days | |

| South America | 25~35 days | WestAfrica | 30~60 days | MiddleEast | 15~30 days | East Asia | 2~3 days | |

| Middle America | 20~35 days | EestAfrica | 23~30 days | Ocenia | 15~20 days | South Asia | 10~25 days | |

FAQ

1.About Sample

We provide free sample for testing.

2.OEM,ODM service available.

3.According to customer's request, packed with pallet or without pallet.

Tile adhesive(20kg/bag)packing with pallet specification:

64 bags/pallet = 1.28 MT/pallet

72 bags/pallet = 1.44 MT/pallet

One full 20ft container max loading 27.6MT.

With pallets can load 1360 bags, without pallet can load 1380 bags.